| |

| Application |

| Chemical Industry: |

| Printing ink, Functional ink, Paint, Latex paint, Building coating, Nano coating, coating auxiliary, Pigment, Dye, Textile |

| auxiliary, Adhesive, Silicone fluid emulsion, Surfactant,Lubricant, Heavy oil emulsion, Diesel oil emulsion |

| Food Industry: |

| Chili sauce, Sesame sauce, Fruit tea, Ice cream, Cream, Jam, Bean paste, Peanut milk, Protein milk, Dairy products, |

| Essence, Condiments, Food and Beverage |

| Daily Chemical Industry: |

| Toothpaste, Detergent, Cosmetics, Spices, Balsam |

| Pharmaceutical Industry: |

| Syrup, Nutrient solution, Ointment, Biologics, Vaccines, Oral liquid, Fungicides, Injections, Antibiotics, Droplets |

| |

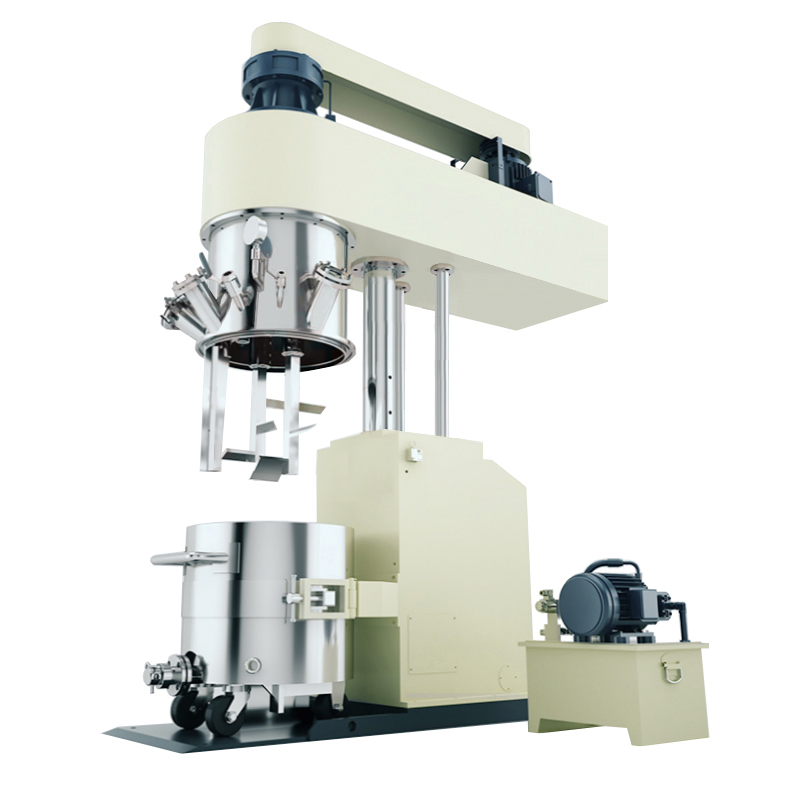

| Performance Advantages |

| Suitable for mixing and emulsifying high viscosity materials. |

| Vacuum material defoaming, solvent evaporation prevention, finer material quality. |

| Easy to operate and safe. stainless Steel electric lifting mechanism, capable of rapid lifting and fixing; The shear |

| rotor fixed to the main shaft with internal hexagonal bolts, easily and quickly replaced, easy to clean. |

| |

|