| |

| |

| Performance Advantages |

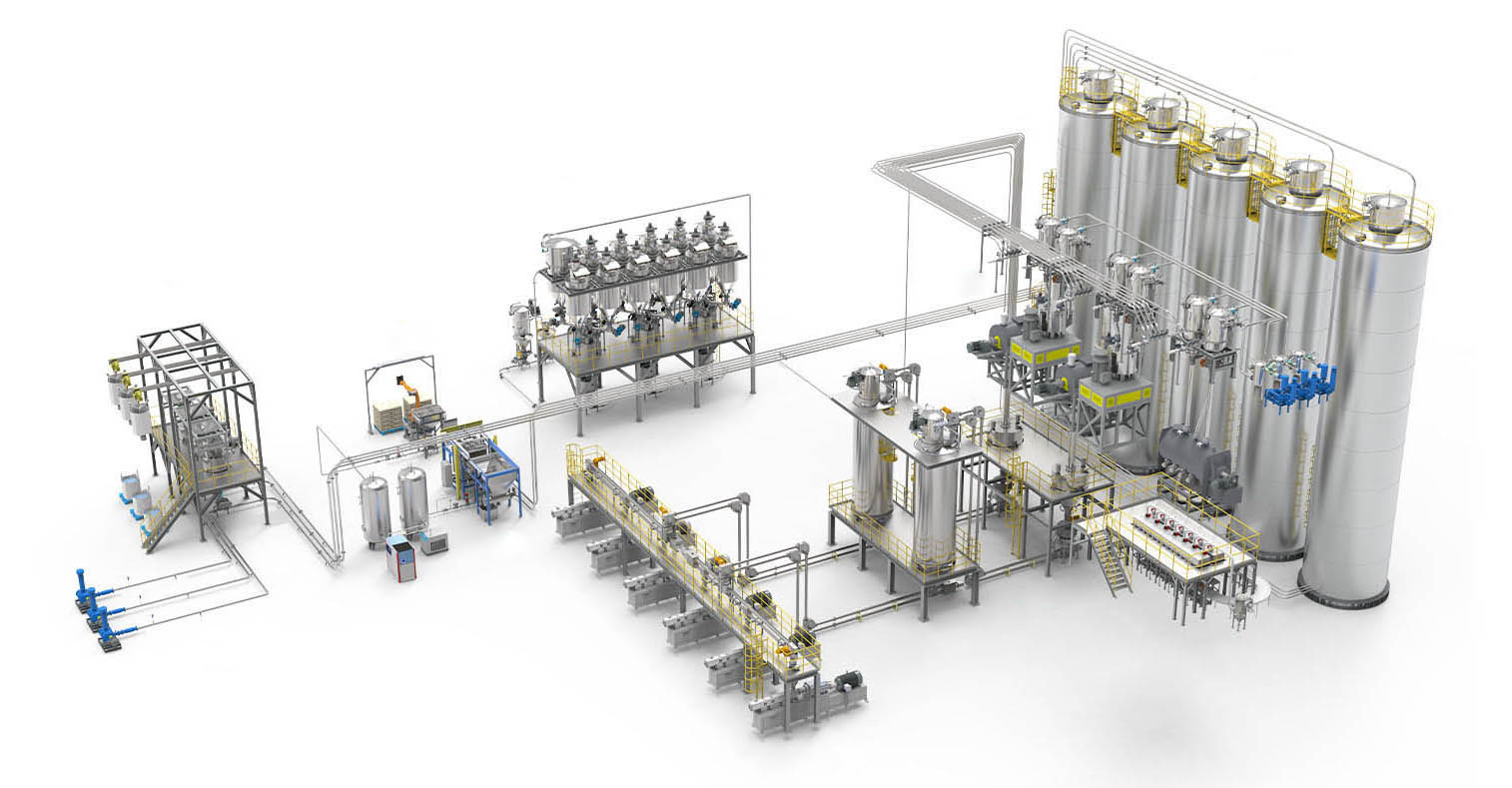

| 1. Nano Powder Integrated Production Line includes Materials feed system, Batching system, High speed dispenser, Nano grinding mill, Sintering furnace, Airflow pulverizer |

| and Automatic controlling system. The entire production can achieve accurate ingredients, stable quality and intelligent control. By selecting appropriate production |

| equipment, automation equipment, control programs and intelligent production management systems, each process is connected in a reasonable, orderly and |

| coordinated manner to maximize product quality and production capacity. |

| 2. Extensive Exerience: |

| Deliveried nearly 40 EPC projects, with extensive experience in production line projects. |

| 3. The production line is highly automated with low labor costs. Intelligent production management ensures stable product quality. |

| 4. Reasonable production line configuration and high production efficiency.The core components of the production line are independently processed and produced, with |

| a high degree of guarantee. |

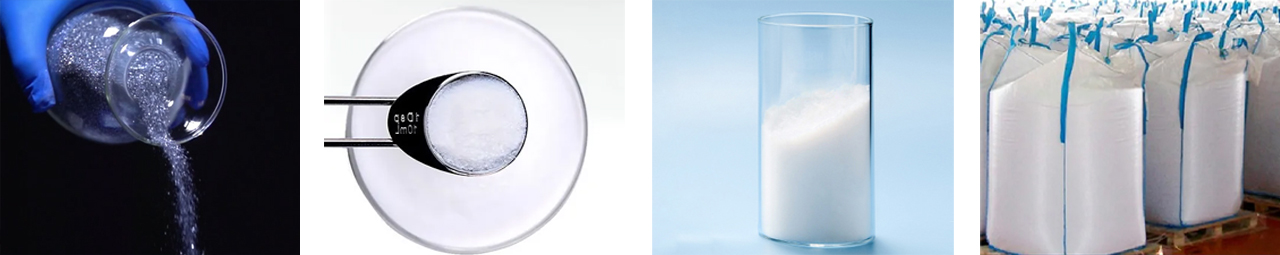

| 5. High precision in ingredient measurement ensures precise formulation, Comprehensive process control testing ensures stable quality. |

| |

| Main Processes and Equipment |

|

|

|

|

|

|

|

|

|

|

|

Feeding System |

|

Batching System |

|

High Speed Dispenser |

|

Nano Bead Mill |

|

Sintering Funance |

|

Airflow Pulverizer |

|

| |